What If We Had Industrial Replicators?

What If We Had Industrial Replicators?

Reimagining Local Manufacturing in a Post-Global Supply Chain Age

What if we already had replicators?

Not the science fiction kind that summon Earl Grey from thin air — but something far more grounded. And more important.

What if we had local, on-demand production hubs powered by licensed digital patterns — capable of producing the goods we need, where we are, when we need them? What if the bottleneck of global shipping and warehouse logistics could be bypassed entirely — not by scaling up, but by scaling down?

The idea struck during the early days of COVID. Global supply chains snapped. Containers marooned at sea. Shelves emptied overnight. It became clear that the system — for all its complexity — was far more fragile than we’d imagined.

I remember wondering: why couldn’t we just… print the things we needed?

At the time, it was the home 3D printer that caught my attention. Not as a novelty for hobbyists, but as infrastructure. Essential. Democratic. But the more I thought about it, the clearer it became: the future wasn’t a printer in every home. Perhaps it was a production hub in every neighbourhood.

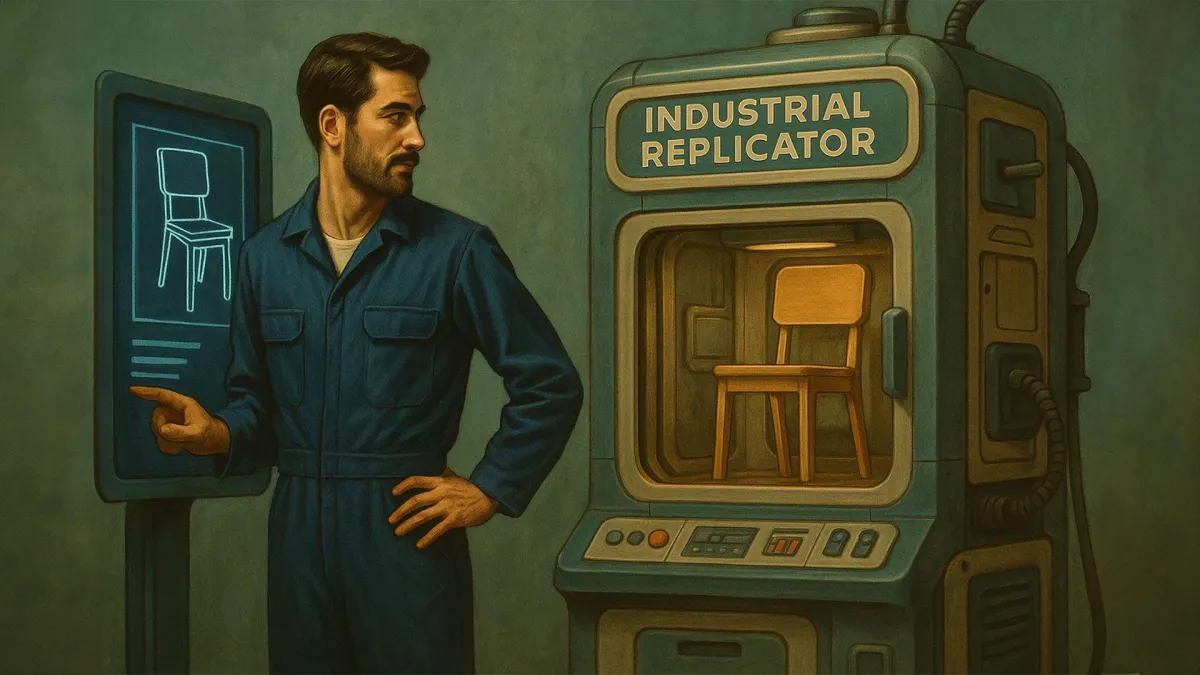

Imagine a small-scale facility — half workshop, half micro-factory — fitted with adaptable tools: 3D printers, CNC routers, textile cutters. No smokestacks. No surplus stock. Just a modular space, stocked with raw inputs and ready to fabricate what the community needs.

I’ve come to think of this model as the Industrial Replicator.

It would draw from a central digital library — a Pattern Buffer — where designers upload licensed blueprints. Local producers could download and fabricate as needed. Smart contracts enforce usage rights. No overproduction. No piracy. Nothing made without a verified request.

From bicycle parts to signage, educational kits to kitchen fittings — production becomes local, responsive, and clean. A contract brewery — but for everything.

But manufacturing is only half the picture.

To truly localise production, we need to localise materials as well.

Recycling, as it stands, is performative. Sorted into bins. Shipped off. What happens next is vague. Often inefficient. What if we reimagined it — not as disposal, but refinement?

A future-ready recycling centre wouldn’t just sort — it would standardise. It would render plastics, metals, fabrics, and composites into replicator-ready formats. A Universal Material Format. Designed to flow.

Suddenly, a broken chair isn’t waste. It’s a joint in a new kitchen.

Discarded packaging becomes the next planter or shelf.

Old parts return as new components — without ever leaving the borough.

It’s circular. Local. Carbon-conscious.

And closer than we think.

Strip away the jargon, and this isn’t sci-fi. It’s simply a smarter loop. Less waste. Shorter lead times. More sovereignty in how communities meet their needs.

And retail changes, too.

Picture a clothing shop that carries only base stock. Patterns are digital. Garments made-to-measure, on demand, using timeless designs. Or a homeware studio — showroom pieces on display, custom specs chosen, fabrication handled locally.

These aren’t hypotheticals. They’re already happening.

A friend of mine is launching a fitness retreat in Vietnam. Instead of importing branded merchandise, he partnered with a local plant that produces bamboo bottles and eco-friendly dishware. The factory laser-etched his branding on-site — clean, low-waste, rooted in place.

Local production. Regional identity. Global tech.

It may sound idealistic. But then again, so did craft beer.

Two decades ago, small-batch breweries were dismissed as romantic distractions. Today, they’re a global force. Why? Because people wanted story. Flavour. Locality.

We’re at a similar threshold in manufacturing.

The Industrial Replicator isn’t utopian. It’s a viable model whose time is coming. It fuses capability with intent. It restores dignity to local work. Rebalances economies from screen to soil. From multinational to micro. It rebuilds a middle class that makes — not offshores — again.

It replaces fragility with resilience.

Abstraction with tangibility.

Excess with precision.

It may not arrive all at once. But it may well be that the most important infrastructure of the next era won’t be high-speed rail or smart cities — it’ll be small, quiet, modular, and a few blocks from your house.

The Industrial Replicator is a seed of an idea.

But if we plant it now — it may take root before the next storm comes.